Iimveliso

-

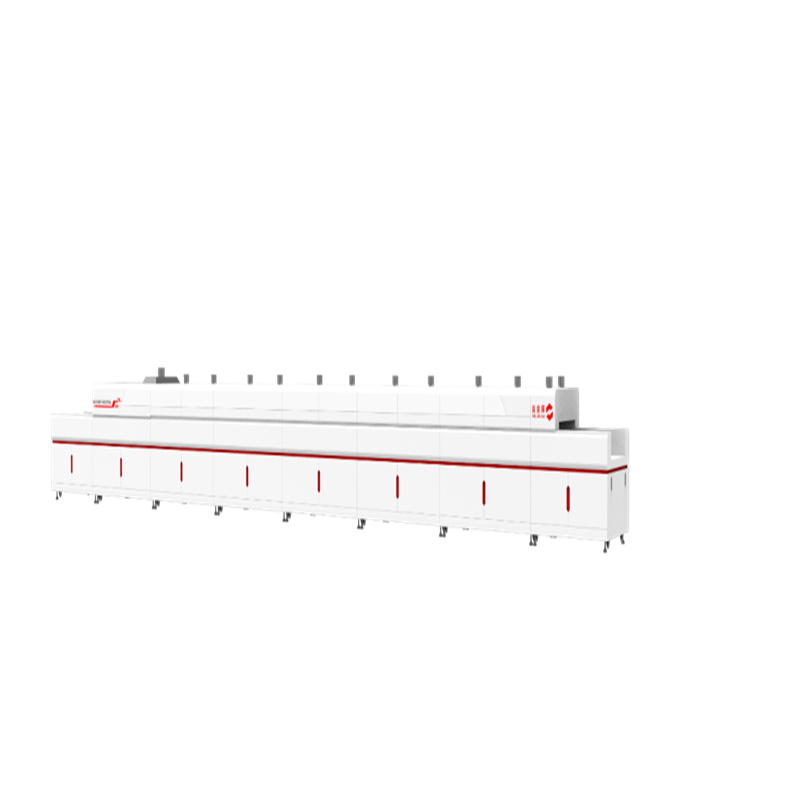

Uhlobo lwe-roller itonela yokomisa i-oveni

Ingcaciso yeMveliso

Ii-oveni zetonela yomoya oshushu ezithunyelwa kushishino zineendawo ezininzi zombane ezifudunyezwayo, ezinokuthi zilawuleke ngokwazo ngenxa yobushushu.Umzekelo, iiPCB zisetyenzwa

hamba kwi-oveni kwaye unqumle indawo nganye ngesantya esilawulwayo kunye nokuhanjiswa kwe-reel rolling.Amagcisa ahlengahlengisa isantya somthuthi kunye namaqondo obushushu wendawo ukuze afezekise ixesha elaziwayo

kunye neprofayile yobushushu.Iprofayile esetyenziswayo inokwahluka ngokuxhomekeke kwiimfuno zeePCBs zisetyenzwa ngelo xesha.

Umatshini wonke uquka icandelo lokutyisa, indawo yokomisa ehambelana nenkqubo yokuvelisa amandla enelungelo elilodwa lomenzi wechiza, inkqubo yokuhambisa umoya, inkqubo yogcino lobushushu, kunye necandelo lokothula.Yamkela uyilo olugqithiswayo lwerola enelungelo elilodwa lomenzi wechiza, ukusebenza okuzinzileyo kunye nesiphumo esihle sokugcina amandla.Ifanelekile kwiibhodi zesekethe zangaphambili / emva kokubhaka. -

I-oveni yokuhambisa itonela egqunyiweyo

Ingcaciso yeMveliso

Ii-oveni ezithunyelelwayo zokuhanjiswa kwemizi-mveliso ziqulathe iindawo ezininzi ezifudunyezwa ngokwahlukeneyo, ezinokuthi zilawulwe ngokuzimeleyo ngokweqondo lobushushu. Isixhobo sokupakishwa sisetyenzwa ngokuhamba kwi-oveni nakwindawo nganye ngesantya esilawulwayo.Amagcisa ahlengahlengisa isantya somthuthi kunye namaqondo obushushu wendawo ukuze afezekise ixesha elaziwayo

kunye neprofayile yobushushu.Iprofayili esetyenziswayo inokwahluka ngokuxhomekeke kwiimfuno zezinto zokuPakisha zisetyenzwa ngelo xesha.

Umatshini wonke wenziwa licandelo lokutyisa, indawo yokomisa ehambelana nenkqubo yokuvelisa amandla enelungelo elilodwa lomenzi wechiza, inkqubo yobushushu bokuhambisa umoya, kunye necandelo lokukhulula.Ukwamkela i-stall yentsimbi ekhethekileyo yoyilo lokuhambisa, ukusebenza okuzinzileyo kunye nefuthe elihle lokonga amandla.Ifanelekile kwi-substrates yephakheji yangaphambili / emva kokubhaka. -

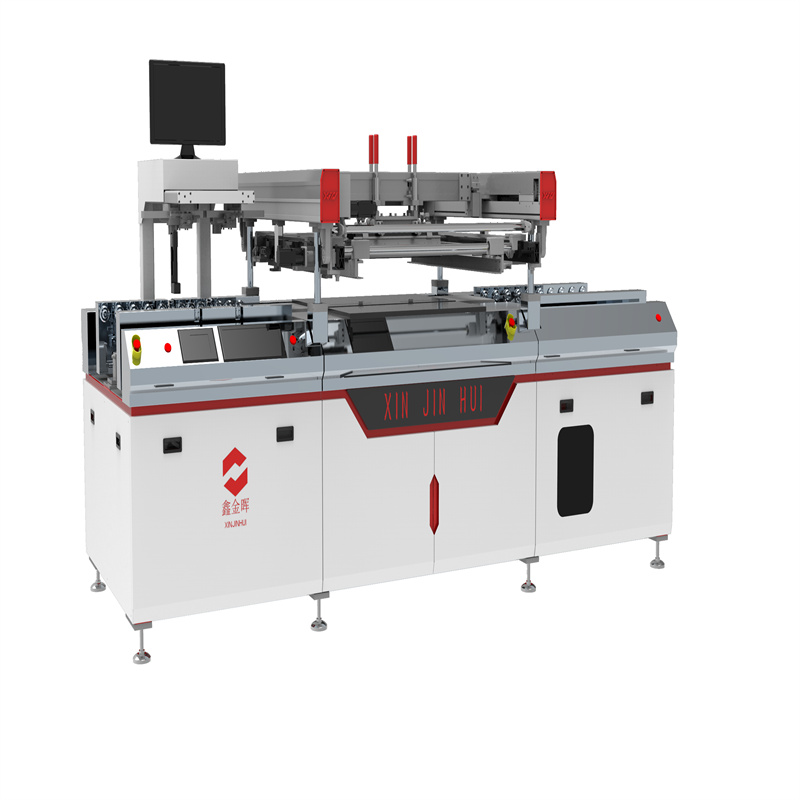

Umatshini wokuprinta wesikrini wesilika ozenzekelayo

1, I-Servo motor iqhuba ukuprinta kunye ne-pneumatic off screen ukuze ibone umsebenzi ohambelanayo wescreen kunye nokuthintela ngokufanelekileyo ukuncamathela kwesikrini.I-servo motor iqhubela isiqwenga sokuprinta ukuba sihambe ngokukhawuleza kwaye ngokucokisekileyo ukuqinisekisa ukuma okuchanekileyo kwesiqwenga sokushicilela.

I-2, i-Servo motor kunye nesikhokelo esichanekileyo sesikhokelo sikaloliwe siqinisekisa indawo echanekileyo kunye nobomi benkonzo obude.Isakhiwo sokuphakamisa esithe tye sesakhelo sokuprinta siqinisekisa ukuba uxinzelelo lwe-scraper lunokulinganisela.

I-3, i-smart interface touch operation, kulula ukuseta, kunye nokufunyanwa kwempazamo ngokuzenzekelayo kunye nokubonisa ingxaki.Uxinzelelo lokushicilela kunye neplate yesikrini inokulungelelaniswa ngokufanelekileyo nangokuchanekileyo, kwaye i-angle ye-scraper inokulungiswa ngokuthanda.

I-4, inkqubo ye-CCD yokulungelelaniswa komfanekiso ngokuzenzekelayo, idityaniswe kunye namaqonga asebenzayo asekhohlo nasekunene, yenza ukusebenza ngokukhawuleza kunye nokuchaneka okuphezulu.Ukulungiswa kwexabiso lezinto ezininzi zenkqubo yemifanekiso akukhawulelwanga nayiphi na imizobo, kwaye nayiphi na imizobo ingasetyenziswa njengenjongo.

-

Umatshini wokuPlagi weSemi-Automatic Pressure

Umatshini wonke unecandelo lawo le-booster system plug hole, elifanele i-viscosity ephezulu ye-inki / iplagi ye-resin.Yamkela uqwalaselo lwezixhobo zombane ezaziwayo-kakuhle, luxhotyiswe ngeengcamango zokuyila eziphambili kunye nomlinganiselo ozinzileyo wesakhiwo somatshini, kwaye ixhaswa ngamanani obuchwepheshe obunelungelo lobunikazi.Ukuqinisekisa imveliso ezinzileyo nethembekileyo kunye nokusebenza kweemveliso.

-

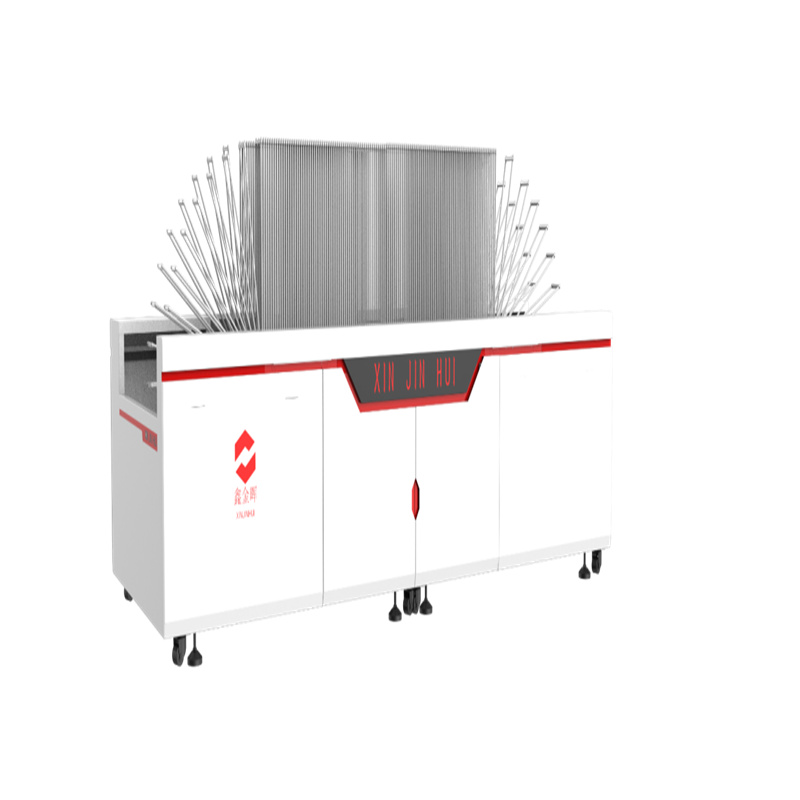

solar Profile Panel Turnover Buffer

Ingcaciso yeMveliso

Umatshini wonke uqulunqwe kwicandelo lokulayisha, i-flap yohlobo lwelanga, kunye necandelo lokukhupha.Ukwamkela uyilo lokuhambisa idiskhi enelungelo elilodwa lomenzi wechiza, ukusebenza okuzinzileyo.Ifanelekile ukuguqulwa kwebhodi yesekethe, ukupholisa kunye nokugcinwa kwexeshana. -

Irejista yokudlulisa ethe tyaba yokuphethulwa kwephepha

Ingcaciso yeMveliso

Umatshini wonke uqulunqwe kwicandelo lokulayisha, i-rack yokugcina yesikhashana kunye necandelo lokukhulula.Ukwamkela i-patent yokujikeleza i-patent rack yokuhambisa uyilo, ukusebenza okuzinzileyo.Ifanelekile ukugcinwa kwesikhashana kweebhodi zeesekethe. -

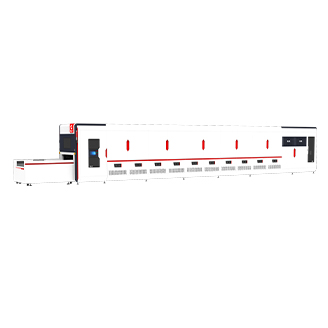

I-Oven yeTunnel ye-Side Clip ye-Conveyor

Ingcaciso yeMveliso

Ii-oveni ezihanjiswayo zokuhanjiswa kwakhona kweshishini zineendawo ezininzi ezifudunyezwayo, ezinokuthi zilawuleke ngokwazo ngenxa yobushushu.IiPCBs zisetyenzwa

hamba kwi-oveni kwaye ujikeleze indawo nganye ngesantya esilawulwayo.Amagcisa ahlengahlengisa isantya somthuthi kunye namaqondo obushushu wendawo ukuze afezekise ixesha elaziwayo

kunye neprofayile yobushushu.Iprofayile esetyenziswayo inokwahluka ngokuxhomekeke kwiimfuno zeePCBs zisetyenzwa ngelo xesha.

Umatshini wonke ulayishwe yiqonga lokumisa ngokuzenzekelayo, kwaye indawo yokomisa ihambelana ne-patent-energy-saving-heater system, inkqubo yokuthutha umoya, inkqubo yokugcina ukushisa, kunye nokutya ngokuzenzekelayo.Yamkela ikliphu yokubamba esecaleni enelungelo elilodwa lomenzi, ukusebenza okuzinzileyo kunye nesiphumo esihle sokugcina amandla.Ifanelekile kwiibhodi zeesekethe zangaphambili./Emva kokugcadiswa. -

Intelligent Pressure Plug-ngePrinta yeSkrini

Ingcaciso yeMveliso

Umatshini wonke uqulunqwe licandelo lolungelelwaniso lwenkqubo yeCCD ekrelekrele ngokupheleleyo,

icandelo lokuplaga nge-booster system, kunye necandelo lokubuyisela izinto eziphathekayo.Ekhohlo

kwaye itafile yesivalo sasekunene ihambisa iindawo ezishicilelweyo kuthotho embindini.Inokuhlangana phezulu

viscosity inki / intlaka plug umngxuma. -

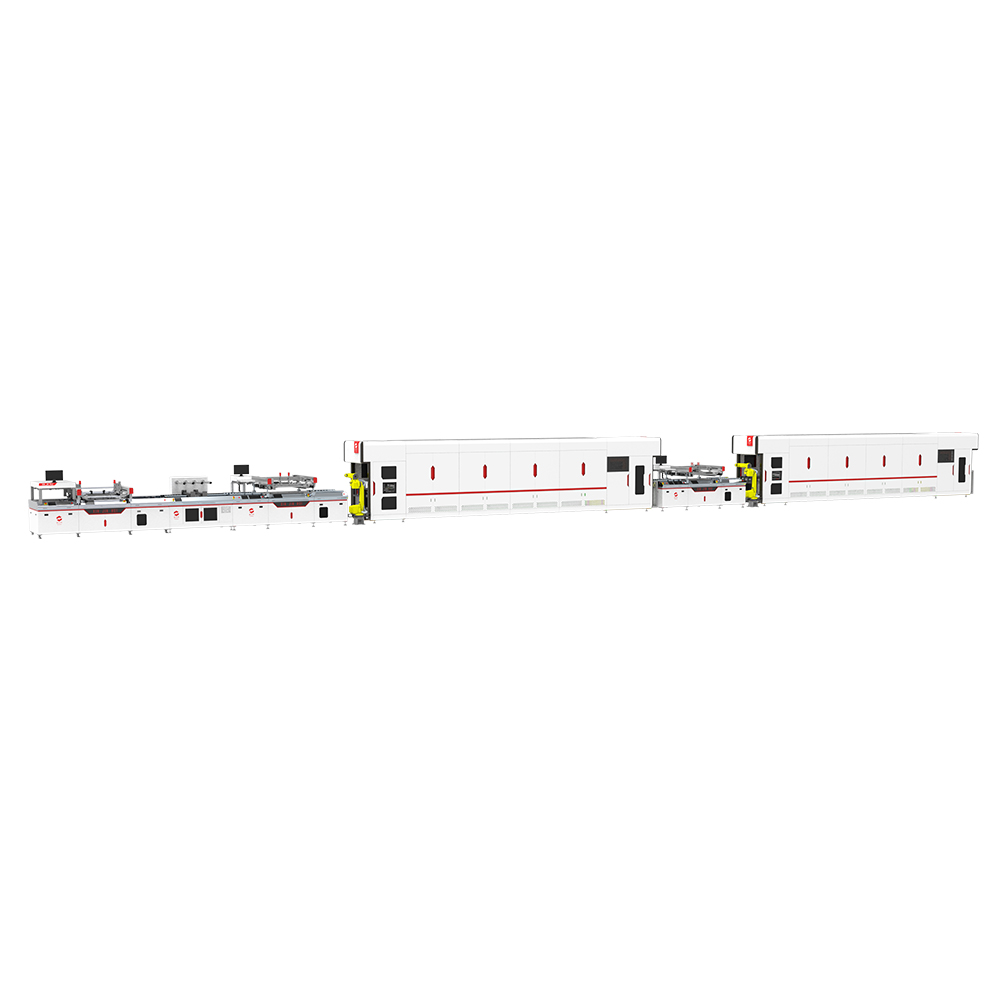

Ngokupheleleyo I-Solder Mask Emithathu eZithukuthuku Qhubeka nokuShicilela

Ukwazisa ngemveliso:Ulungelelwaniso lwesixhobo somgca wemveliso: uxinzelelo olukrelekrele lokuplaga-ngomatshini → umatshini wokulinganisa ozenzekelayo → Umshicileli wesikrini semaski somthengisi okrelekrele → indawo ezenzekelayo jika →B umshicileli okrelekrele wesikrini semaski somthengisi → i-oveni ye-conveyor ye-turnnel esecaleni.

Ukuplaga okuzenzekelayo okuzenzekelayo-ngomgca wokushicilela imaski ye-solder: iyasebenza kwi-PCB solder imaski yokushicilela inkqubo yokushicilela i-multilayer panel, iibhodi zesekethe ezibhityileyo / ezishinyeneyo.Yamkela uqwalaselo lwezixhobo zombane ezaziwayo-kakuhle, ithwala iikhonsepthi zokuyila eziphambili, i-stable mechanical structure , kwaye ixhaswa ngenani letekhnoloji enelungelo elilodwa lomenzi wechiza.Ukuqinisekisa imveliso ezinzileyo nethembekileyo kunye nokusebenza kweemveliso. -

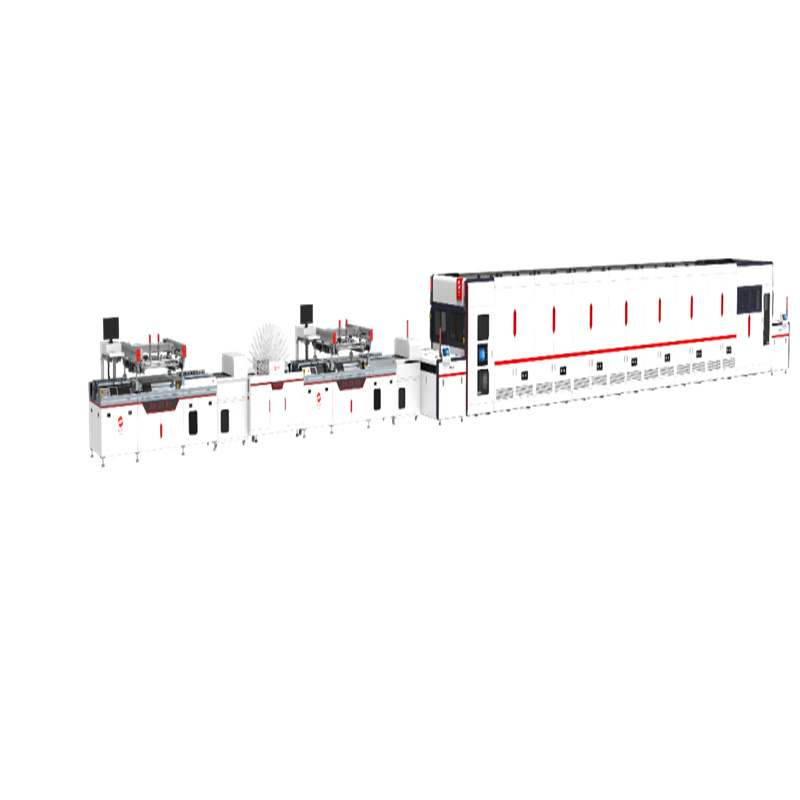

Ngokupheleleyo Umgca Wokuprinta weMaski eSolder eThin

Ukwazisa ngemveliso: Uqwalaselo lwesixhobo somgca wemveliso: uxinzelelo olukrelekrele lokuplaga-ngomatshini → umatshini wokulinganisa ozenzekelayo → Umshicileli wesikrini semaski somthengisi okrelekrele → i-oveni yokuhambisa exhonyiweyo →B umshicileli okrelekrele wesixhobo sokuhambisa imaski → i-oveni yokuhambisa exhonyiweyo

Umgca wokuvelisa imaski yepleyiti ecwengileyo ezenzekelayo: iyasebenza kwinkqubo yoshicilelo lwe-inki ye-inki yokuprinta yamanani amaninzi, iibhodi zesekethe ezibhityileyo / ezishinyeneyo.Ithatha i-hardware yombane eyaziwayo ukucwangciswa kwe-hardware ekhaya nakwamanye amazwe, ithwala iikhonsepthi zokuyila eziphambili, i-stable mechanical structure , kwaye ixhaswa ngenani lobuchwepheshe obunelungelo lobunikazi.Ukuqinisekisa imveliso ezinzileyo nethembekileyo kunye nokusebenza kweemveliso. -

Ngokupheleleyo Automatic PCB Legends Screen Printing Line

Ukwazisa ngemveliso:Ulungelelwaniso lwesixhobo somgca wemveliso: Umatshini woshicilelo wesikrini okrelekrele → umatshini we-uv →umatshini wokushibilika welanga → B umshicileli wesikrini okrelekrele → i-oven ye-wicket yokuhambisa i-oven. inciphisa iindleko zabasebenzi, kodwa iphinda ifezekise injongo yokonga amandla kunye nokunciphisa i-carbon (ukusuka kwi-original pass two-pass printing kunye nokubhaka kabini ukuya kwiipasi ezimbini zokushicilela kunye nokubhaka enye).

Iintsomi ezipheleleyo zePCB ezizenzekelayo zomgca woshicilelo lwesikrini: uyasebenza kwiintsomi zePCB inkqubo yoshicilelo lwesikrini sephaneli yemultilayer, iibhodi zesekethe ezibhityileyo / ezishinyeneyo.Yamkela uqwalaselo lwezixhobo zombane ezaziwayo-kakuhle, ithwala iikhonsepthi zokuyila eziphambili, i-stable mechanical structure , kwaye ixhaswa ngenani letekhnoloji enelungelo elilodwa lomenzi wechiza.Ukuqinisekisa imveliso ezinzileyo nethembekileyo kunye nokusebenza kweemveliso.