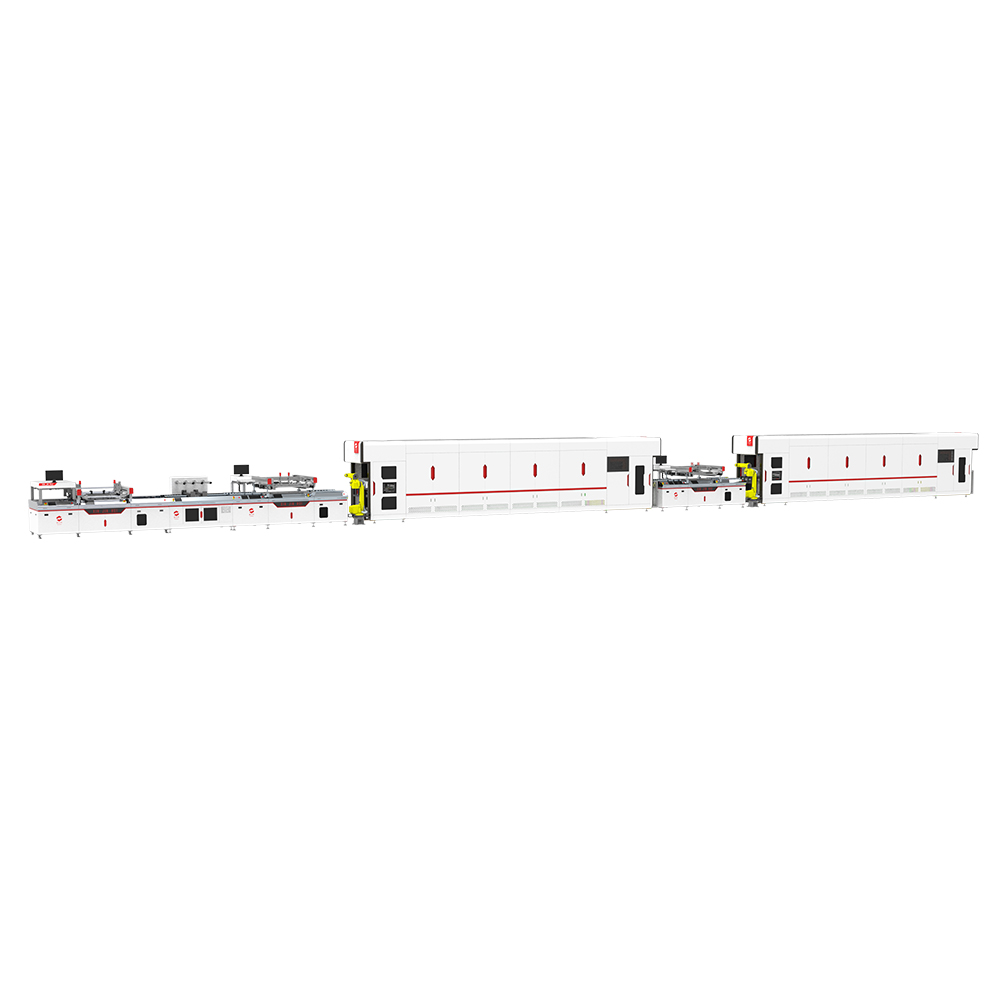

Ngokupheleleyo Umgca Wokuprinta weMaski eSolder eThin

Inkqubo yokulungelelaniswa kweCCD yamkelwa, kwaye inombolo yezinto eziphathekayo itshintshelwe kwi-3-5min

Iyahambelana nokuveliswa kweeplati ze-0.4mm-3.0mm

Umthamo wemveliso ufikelela kwi-3-6pnl / min

Qonda [idijithali], [iparameterisation] kunye [nobukrelekrele]

I-Manipulator ilayisha kwaye ikhuphela ukuqonda umgca wonke ngokuzenzekelayo

I-PLC:Mitsubishi

Isikhokhelo sikaloliwe:THK

Isilinda:I-AIRTAC

Unxibelelwano:Mitsubishi

Isikrini esibanjwayo:weinview

Ibhanti ye-synchronous:Megadyne

Ukuthwala:NSK

Isikrufu sebhola:I-TBI

Ubungakanani boBulungisa

Ubuninzi: 620mm * 720mm

Ubuncinci: 400mm * 400mm

UkuXhobisa ukutyeba

Ubukhulu obukhulu: 3.0mm

Thinnest: 0.4mm

Ubuchule boMveliso

Ubuninzi: 6pnl / min

Ubuncinci: 3pnl / min

Ubhaliso olubonakalayo: 2 iikhamera zeCCD zokubona uphawu lobhaliso okanye umngxuma kwi-substrate ngokukhawuleza, ukubala ngokwezibalo indawo ngaphandle-seti imali ebonelela kwinkqubo yolawulo, inkqubo yosasazo ye-X/Y servo iqhuba itheyibhile yobhaliso kwangoko ukuya kwindawo echanekileyo.

Indawo yeLaser:Imodyuli yekhamera yeCCD itshixiwe / ivulwe ngokutshintsha kolawulo lwe-pneumatic, ukufuduka ngokukhawuleza kunye nokulungiswa kwesandla ngasemva / ngasekunene ngasekhohlo, idityaniswe ngentelekelelo yenqaku lelaser ukuze ihambe ngokukhawuleza kwindawo ekujoliswe kuyo.

Uhlengahlengiso oluNcinci lweSkrini soLawulo lweDijithali:buyisela imanuwali amanqaku amathathu uhlengahlengiso oluncinci, olungakwaziyo ukuhlengahlengisa ngokuchanekileyo ukufumana indawo eceliweyo, imbuyekezo yolawulo lwedijithali ifumana impumelelo echanekileyo ekhawulezileyo.

Buffer Stacker:xa umshicileli wesikrini esisecaleni u-B eyeka ukucocwa kwesikrini, Icala elingenayo emva kokuprintwa, isitakhi sethutyana kwisithinteli esipakishweyo ukunqanda ifuthe lokwenziwa kwemveliso.

UkuJika kwisikhundla esizenzekelayo: ifezekisiwe A side legend yoshicilelo kwaye ithuthwe ukujika, servo drive CCD ukubona uphawu lobhaliso kwicala B kushicilelo legend.

I-Clipper Flattening:I-substrate ikhubazeke emva kokucutshungulwa okuhlukeneyo, i-clipper iyatsala ukwandisa amacala amabini athambileyo ngelixa ijika ukuze iququzelele ukubhaliswa kweCCD, ngakumbi ukusebenza kwefilimu ebhityileyo ebalaseleyo.