Inkqubo yemaski yebhodi yesekethe ye-PCB yenye yekhonkco eliphambili kwinkqubo yokwenziwa kwe-PCB, kwaye imiba yomgangatho wayo inempembelelo ebalulekileyo ekusebenzeni kunye nokuthembeka kwe-PCB.Kwinkqubo ye-mask ye-solder, iingxaki ezisemgangathweni eziqhelekileyo ziquka ii-pores, i-solder yobuxoki, kunye nokuvuza.Ezi ngxaki zingakhokelela kuphela ekucutheni ukusebenza kwePCB kunye nokuthembeka, kodwa zinokuzisa ilahleko engeyomfuneko kwimveliso.Eli nqaku liza kwazisa iindlela ezisebenzayo zokusombulula ezi ngxaki kunye nokuphonononga ukusetyenziswa koomatshini bokushicilela be-PCB solder mask screen ekusombululeni ezi ngxaki.

1. Inkcazo yeengxaki zomgangatho oqhelekileyo kwi-PCB solder mask process

1. Stomata

I-Porosity yenye yeengxaki eziqhelekileyo zomgangatho kwi-PCB solder mask process.Ikakhulu ibangelwa kukuphelelwa ngokwaneleyo kwegesi kwi-solder mask material.Ezi pores ziya kubangela iingxaki ezifana nokusebenza kakubi kombane kunye neesekethe ezimfutshane kwi-PCB ngexesha lokucubungula kunye nokusetyenziswa okulandelayo.

2. I-soldering ebonakalayo

I-Welding ibhekisela kuqhagamshelwano olubi phakathi kwe-PCB pads kunye namalungu, okukhokelela ekusebenzeni kombane okungazinzanga kunye nesekethe emfutshane elula okanye isekethe evulekileyo.I-soldering ebonakalayo ibangelwa ikakhulu kukunganyaniseki okwaneleyo phakathi kwezinto eziphathekayo zemaski kunye ne-pad okanye iiparameters zenkqubo engafanelekanga.

3. Ukuvuza

Ukuvuza kuxa kukho ukuvuza okukhoyo phakathi kweesekethe ezahlukeneyo kwi-PCB okanye phakathi kwesekethe kunye nenxalenye esekelwe phantsi.Ukuvuza akuyi kuchaphazela kuphela ukusebenza kwesekethe, kodwa kunokubangela imiba yokhuseleko.Izizathu zokuvuza zingabandakanya imiba esemgangathweni kunye nezixhobo zemaski ze-solder, iiparamitha zenkqubo engafanelekanga, njl.

2. Isisombululo

Ukujongana nale miba yomgangatho ungentla, ezi zisombululo zilandelayo zinokuthathwa:

Kwingxaki ye-pores, inkqubo yokugquma i-solder resistant material ingalungiswa ukuze kuqinisekiswe ukuba izinto eziphathekayo zingena ngokupheleleyo phakathi kwemigca, kwaye inkqubo yokubhaka kwangaphambili inokongezwa ukukhupha ngokupheleleyo igesi kwi-solder resist material.Ukongeza, unokongeza uhlengahlengiso loxinzelelo lwe-scraper emva kokuprintwa kwesikrini ukunceda ukuphelisa iipores.Apha sincoma ukuba ufunde malunga nomatshini wokuplaga we-solder mask hole okrelekrele ngokugqibeleleyo kunye nenkqubo yawo yoxinzelelo.Nge-6 ~ 8 kg yegesi, inokufezekisa I-scraper inokuzalisa umgodi nge-stroke enye kwaye ikhuphe ngokupheleleyo igesi.Akukho mfuneko yokuphinda usebenze umngxuma weplagi ngokuphindaphindiweyo.Isebenza kakuhle, igcina ixesha kunye nenkathazo, kwaye inciphisa kakhulu izinga le-scrap.

Kwingxaki ye-solder ye-solder, inkqubo inokulungiswa ukuze kuqinisekiswe ukunamathela okwaneleyo phakathi kwezinto eziphathekayo ze-mask kunye ne-pad.Ngexesha elifanayo, ngokubhekiselele kwiiparameters zenkqubo, ukushisa kokubhaka kunye noxinzelelo kunokunyuswa ngokufanelekileyo ukuze kuphuculwe ukunamathela phakathi kwezinto zokumelana ne-solder kunye ne-pad.

Ngeengxaki zokuvuza, ukulawulwa komgangatho wezinto zokumelana ne-solder kunokuqiniswa ukuze kuqinisekiswe ukusebenza kombane okuzinzileyo.Ngexesha elifanayo, ngokubhekiselele kwiiparamitha zenkqubo, ukushisa kokubhaka kunye nexesha kunokunyuswa ngokufanelekileyo ukuze kuqiniswe ngokupheleleyo izinto zokumelana ne-solder, ngaloo ndlela kuphuculwe ukusebenza kwe-insulation yesekethe.

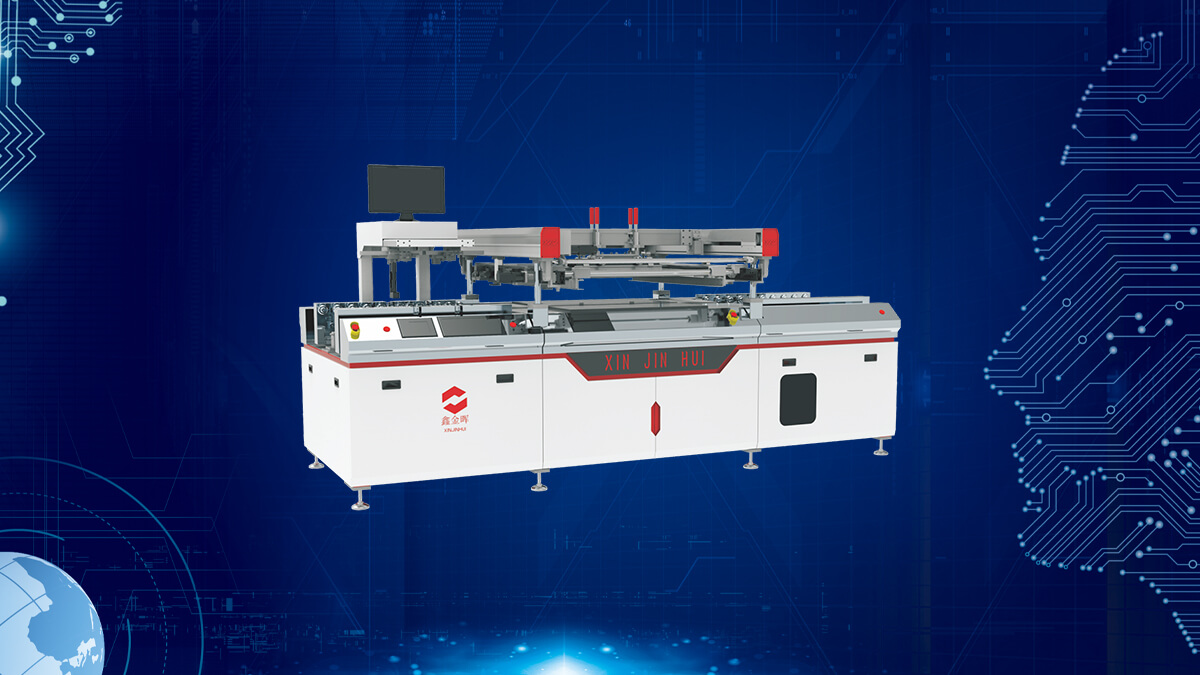

3. Ukusetyenziswa komatshini wokushicilela we-Xinjinhui PCB webhodi yesekethe ye-solder

Ukuphendula kwiingxaki zomgangatho ongentla, i-Xinjinhui PCB solder mask inokubonelela ngezisombululo ezisebenzayo.Isixhobo samkela itekhnoloji yoshicilelo oluphezulu lwesikrini, esinokulawula ngokuchanekileyo isixa sokugquma kunye nesikhundla sempahla ye-mask ye-solder, ukuphepha ngokufanelekileyo ukwenzeka kweepores kunye ne-solder yobuxoki.Ngelo xesha, izixhobo nazo zinomsebenzi wokulawula inkqubo ehlakaniphile, enokutshintsha ngokukhawuleza amanani ezinto eziphathekayo kwi-3 ukuya kwimizuzu ye-5 ngaphandle kwesidingo sokulungelelaniswa kwe-handwheel kunye nokudibanisa inkqubo yokulungelelaniswa okupheleleyo ukuze kuqinisekiswe ukuba i-solder mask screen printing ichanekile kwaye iyasebenza. .

Ukuziqhelanisa kuye kwabonisa ukuba ukusetyenziswa kwebhodi yebhodi ye-solder ye-Xinjinhui PCB yebhodi yokushicilela umatshini wokushicilela unokuphucula ngokufanelekileyo umgangatho kunye nokusebenza kwemveliso yenkqubo ye-solder ye-PCB.Ukusetyenziswa kwesi sixhobo akunakunciphisa kuphela ukuveliswa kweemveliso ezineziphene kunye nokuphucula ukusebenza kakuhle kwemveliso, kodwa kwakhona kubonelele abathengi ngeemveliso zePCB ezikumgangatho ophezulu ukuhlangabezana neemfuno ezahlukeneyo zesicelo.

4. Isishwankathelo

Eli nqaku lazisa iingxaki zomgangatho oqhelekileyo kunye nezisombululo kwinkqubo yemaski ye-solder ye-PCB, igxininise ekusetyenzisweni kwe-Xinjinhui PCB yebhodi yesekethe yebhodi yokushicilela umatshini wokushicilela isikrini ekusombululeni ezi ngxaki.Ukuziqhelanisa kubonise ukuba ukusetyenziswa kwe-solder ukumelana kunokuphucula ngokufanelekileyo umgangatho kunye nokusebenza kwemveliso ye-PCB ye-solder yokuxhathisa inkqubo, ukunciphisa ukwenzeka kweemveliso eziphosakeleyo, kunye nokuphucula ukusebenza kakuhle kwemveliso.Kwangaxeshanye, esi sixhobo sinokubonelela abathengi ngeemveliso ezikumgangatho ophezulu wePCB ukuhlangabezana neemfuno ezahlukeneyo zesicelo.Izisombululo kunye neendlela ezichazwe nguXin Jinhui kweli nqaku zinokubonelela ngereferensi ethile kunye nesikhokelo kumashishini afanelekileyo.

Ixesha lokuposa: Mar-20-2024