Kwishishini lokuvelisa i-electronics, ibhodi yesekethe oomatshini bokuplaga i-inki kunye nokomisa ziinkqubo eziphambili zekhonkco kwimveliso yebhodi yePCB.Badlala indima ebalulekileyo ekuqinisekiseni umgangatho weebhodi zePCB kunye nokuphucula ukusebenza kakuhle kwemveliso.Khumbuza abavelisi bebhodi ye-PCB ukuba izixhobo zomenzi ngamnye zineenkalo ezahlukeneyo kunye neempawu.Ukuba ukuhambelana akukuhle, kunokubangela iziphumo ezibi.Okulandelayo, i-Xin Jinhui iya kuhlalutya kuwe imfihlelo yokutshatisa umatshini wokufaka i-inki we-PCB kunye ne-tonnel furnace, kunye nendlela yokunceda abavelisi be-PCB bafezekise ukuphindwa kabini kwenkqubo efanelekileyo.

PCB ibhodi yesekethe inki yokuplaga linyathelo elibalulekileyo kwinkqubo yoshicilelo.Injongo yalo kukuqinisekisa ukutywinwa kwemingxuma ukubonelela ngokufanelekileyo kunye nokuzinza.Ukomisa itonela yinkqubo ebalulekileyo esekelwe kule nto.Iqinisa i-inki ngokubhaka okunobushushu obuphezulu ukunyusa ngakumbi ukutywinwa kwemingxuma.

Ngethuba lenkqubo yokomisa i-oven ye-tunnel, i-PCB ibhodi yesekethe yebhodi ye-inki imingxuma yeplagi inokuthintela ngokufanelekileyo umswakama ukuba ungangeni, ngaloo ndlela ikhusela ibhodi yesiphaluka kumonakalo womswakama.Kwangaxeshanye, ukutywinwa kakuhle komngxuma we-inki yeplagi kukwaqinisekisa uzinzo lobushushu ngaphakathi kwitonela, okwenza inkqubo yokomisa ifane kwaye isebenze kakuhle.Ke ngoko, unxibelelwano phakathi kokufakwa kwe-inki kunye nokomisa itonela kunokuthiwa kuyancedisana kwaye akunakwahlulwa.

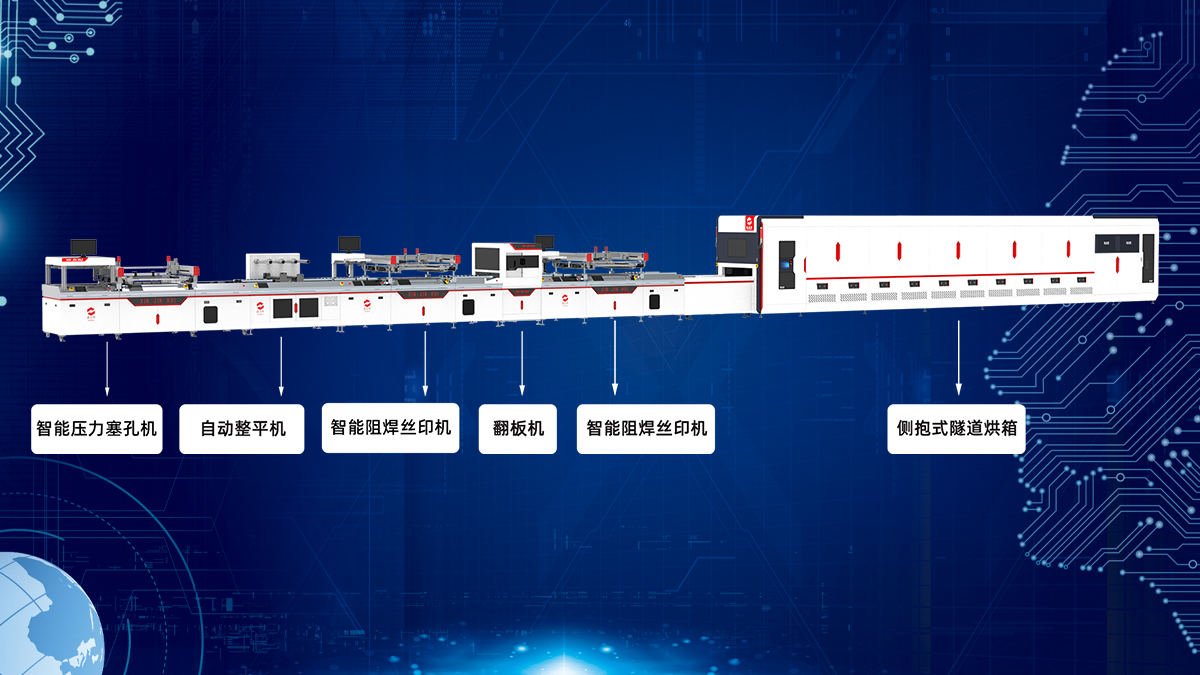

Ukuze kuphuculwe ngakumbi ukusebenza kakuhle kwemveliso kunye nomgangatho, iinkampani ezininzi zokuvelisa sele ziqalisile ukwazisa itekhnoloji enengqondo ezenzekelayo yokutshintsha.Ngokomzekelo, imigca yemveliso ezenzekelayo inokugqiba ngokuzenzekelayo iinkqubo ezifana ne-PCB inki yokuplaga kunye nokomisa, ukunciphisa ungenelelo lwezandla kunye nokuphucula ukusebenza kakuhle kwemveliso.Kwangaxeshanye, inkqubo yokulawula ekrelekrele inokubeka iliso kwinkqubo yokuvelisa ngexesha langempela, ilawule ngokuchanekileyo izixhobo, inciphise ukusetyenziswa kwamandla, nokuphucula ukusebenza kakuhle kokusetyenziswa kwamandla.

Ukukhetha izixhobo ezonga amandla nako kubaluleke kakhulu.Umzekelo, ukusebenzisa izixhobo eziphezulu zokomisa kunye neenkqubo zokulawula ezikrelekrele kunokunciphisa ukusetyenziswa kwamandla.Kwangaxeshanye, ngeenkqubo zolawulo ezikrelekrele, unxibelelwano phakathi kwezixhobo luqondwa ukuze kuphuculwe ngakumbi ukusebenza kakuhle kokusetyenziswa kwamandla.Ngokomzekelo, izixhobo zokumisa kunye nezixhobo zokupholisa zidibene kunye ukuze zilungelelanise ngokuzenzekelayo ixesha lokumisa kunye nexesha lokupholisa ngokuhambelana nobushushu, ngaloo ndlela kugcinwa amandla.

Oomatshini bokufaka i-inki be-PCB beSintu badla ngokuba nemingxunya yeplagi engonelanga ngenxa yeengxaki ezifana noxinzelelo olunganelanga kunye nokungachaneki okwaneleyo, kwaye kufuneka imingxuma yokuplaga ngokuphindaphindiweyo.Okwesibini, ukwenzela ukuxazulula ingxaki yemingxuma yeplagi eyaneleyo, indlela yokunciphisa i-inkinki yoxinaniso isetyenziselwa ukomisa okulandelayo.Ukomisa kuneemfuno eziphezulu zokumisa ubushushu kunye nexesha.Kwangaxeshanye, amandla okucutha okwenziwa ngexesha lokubhaka makhulu kakhulu, anokukhokelela ngokulula kwi-voids, ukuncipha kwe-inki kwi-orifice, kunye ne-yellowing emaphethelweni, nto leyo ebizwa ngokuba yi-golden hole phenomenon, ebaluleke kakhulu. yePCB.Umgangatho we-PCB unobungozi kakhulu, ngoko ke esi siphumo asimkelwanga ngokubanzi kwiindawo zesicelo ezinomgangatho ophezulu we-PCB.

Njengomvelisi onamandla okhethekileyo kuphando lweteknoloji kunye nophuhliso lwezixhobo zokuvelisa ezizenzekelayo zokuplagi ze-PCB, i-PCB solder mask screen printing, kunye neenkqubo zokomisa isikrini se-PCB, i-Xinjinhui iye yaqulunqa ngokukodwa kwaye yaphuhlisa umatshini wokuplaga woxinzelelo olukrelekrele ukujongana namanqaku anjalo entlungu. yahlukile kwi-inki ye-PCB yesintu yokuplaga.Umatshini, inkqubo yokunyusa i-self-developed, i-kilogram yoxinzelelo lomoya inokufikelela kwi-6-8KG, idibene ne-self-locking mechanism kunye nenkqubo yokunyusa amandla ekholamu ezine ukuqinisekisa ukulingana okuchanekileyo kunye nokuzinza.Umngxuma weplagi ugcwele imela enye, ukuphelisa imfuno yokusebenza ngokuphindaphindiweyo kunye nokusebenza ngokutsha kwebhodi ye-scrap, ukuphucula ngokubanzi ukusebenza kakuhle kunye nokwandisa umthamo wokuvelisa Ngexesha elifanayo, zonke iintlobo zelahleko kunye nenkunkuma ziyancipha kakhulu;ngenxa yokuba ukusetyenziswa kwe-Xinjinhui ekrelekrele ngokugqibeleleyo umatshini wokuplaga we-pcb we-inki unokufikelela kwisiphumo esifanelekileyo sokuplaga, ubushushu bokubhaka kwinqanaba lokumisa elilandelayo bunokuba phezulu, ngaloo ndlela gcina ixesha lokubhaka ngeeyure eziyi-1 ~ 2, ukuphucula ngokubanzi iinzuzo ezibanzi zalo lonke. inkqubo, kwaye ukonga amandla Xinjinhui phezulu kangangoko 35%, nto leyo ekhokelayo kushishino.Inokonga iindleko ezininzi zamandla kumashishini, ithomalalise uxinzelelo lokusetyenziswa kwamandla kubavelisi bePCB, kwaye ibonelele ngesiseko sovavanyo lwenqanaba lokusingqongileyo.Nika uncedo olunamandla.

Ngamafutshane, imingxunya yeplagi yebhodi yesekethe yePCB kunye nokoma kwetonela ziqhagamshelwe ngokusondeleyo kwaye zizikhonkco zenkqubo kwimveliso yebhodi yePCB.Ngokuzisa ababoneleli bePCB-ezikhethekileyo ezizenzekelayo ezizenzekelayo kunye nezixhobo zokugcina amandla ezifana ne-Xin Jinhui, sinokukhetha izixhobo ezinomgangatho ophezulu wamandla, iqondo eliphezulu lokuzenzekelayo okunengqondo, ukunciphisa ukuxhomekeka kwabasebenzi, ukwandisa ukucwangciswa kwendawo yomgca wemveliso, ukomeleza ulawulo lwemveliso kunye ukwandisa imarike, njl. Oku kuqhuba abavelisi be-PCB ukuba bafezekise iinjongo zemveliso eziphezulu kunye nomgangatho ophezulu, ngaloo ndlela begcina isikhundla sabo esiphezulu kwimarike.

Ixesha lokuposa: Mar-18-2024