Ishishini lebhodi yesekethe PCB ibisoloko ineemfuno ezingqongqo zomgangatho wenkqubo yemveliso.Phakathi kwabo, ubomvu bebhodi yesekethe ye-PCB ebangelwa ukushicilelwa kwesikrini semaski ye-solder yinto eqhelekileyo engafunekiyo.Ayichaphazeli kuphela i-aesthetics yangaphandle ye-PCB, kodwa iphinda ichaphazele ibhodi yesiphaluka.Kukho nemingcipheko esemgangathweni ekusebenzeni.Eli nqaku - pcb Equipment Network iya kukukhokelela ukuba ube nokuqonda olunzulu oonobangela kunye nezisombululo ukubabomvu kwebhodi PCB okubangelwa solder imaski yoshicilelo lwesikrini kwibhodi yesekethe PCB.

1. Isizathu sokuba ibhodi yesekethe ye-PCB yebhodi ye-solder imaski yoshicilelo lwesikrini ibangela ububomvu kumphezulu webhodi

1. Ubukhulu bomaleko wemaski ye-solder abukho kumgangatho okanye kukho amaqamza ashiyekileyo:

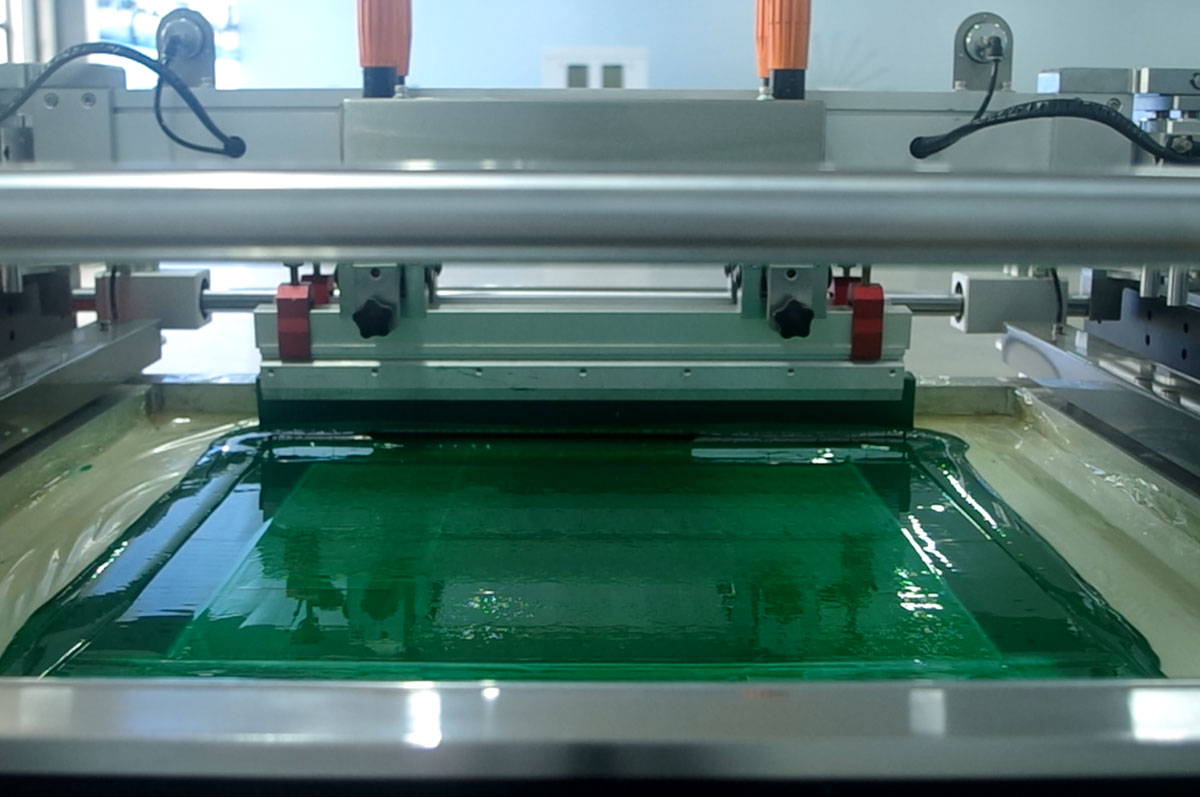

Umaleko we-mask we-solder ubhekiselele kuluhlu lokukhusela olugqunywe kwibhodi yesiphaluka emva kokuprintwa nge-inki ye-mask ye-mask screen ukukhusela isiphaluka ekuchatshazelwe yizinto ezifana nokusingqongileyo kwangaphandle;xa ubukhulu bomaleko wemaski ye-solder bungekho kumgangatho okanye kukho amaqamza ashiyekileyo, kuyafuneka Ngeli nqanaba, iimpendulo ze-oxidation ziqhele ukwenzeka xa zidibana nemekobume zobushushu obuphezulu, okukhokelela kububomvu kumphezulu webhodi, okukhokelela ekuhluphekeni. PCB umgangatho.

Ukuba i-inki ngokwayo esetyenziselwa ukushicilelwa kwesikrini semaski ye-solder ineengxaki ezisemgangathweni, ezifana ne-inki ephelelwe yisikhathi kunye nokwanda kwe-viscosity ye-inki, inokubangela ukuba umphumo okhuselayo we-solder mask umaleko ungaphumeleli, okanye awunakugubungela ngokupheleleyo isiphaluka, ukushiya izithuba kunye nezinye. izithuba ezisemgangathweni, ekugqibeleni zikhokelela kwizinto ezingafunekiyo ezinje ngobubomvu kumphezulu webhodi kunokubangela imingcipheko engaziwayo kunye neempembelelo ekusebenzeni kwayo kunye nomgangatho.

3. I-inki ye-Flux kunye ne-solder imaski ayihambelani:

Umgangatho ombi wePCB eprintiweyo iibhodi zeesekethe zidla ngokuvela kulungelelwaniso lweenkqubo ezinxulumeneyo okanye ezimeleneyo.Ngokomzekelo, i-flux kunye ne-solder yokumelana ne-inki ayihambelani okanye ayihambelani, enokuthi iholele kwiingxabano, utshintsho lwepropathi, njl., okubangelwa ubomvu bomgangatho webhodi.

2. Ukusombulula izicwangciso PCB ibhodi yesekethe solder imaski yoshicilelo lwesikrini ebangela ububomvu kumphezulu webhodi

1.PCB ibhodi yesekethe solder imaski isikrini soshicilelo-kwangaphambi-ukwenziwa kwengcaciso yokwenziwa ngcono:

Ukukhethwa kwe-inki ye-Solder yemaski, ukumodareyithwa kwe-inki ye-inki, ubomi beshelufu ye-inki, i-flux kunye nezinye izinto ezihambelanayo zokulawula umgangatho kunye nemigangatho yokusebenza, ukwenza iiparamitha kunye namanyathelo okuphepha iingozi ze-PCB zesiphako ezibangelwa yizinto eziluhlaza.

2.PCB ibhodi yesekethe solder imaski isikrini ukuprinta-in-imveliso inkqubo yokusebenza:

Umatshini wokuprinta wesikrini sebhodi yesekethe yePCB ushwankathela ngokuqhubekayo kunye nokulungiswa kweempazamo kwaye wenze ulungelelwaniso lweparameter esemgangathweni olusekwe kwiimfuno zoshicilelo ukuze kuqinisekiswe ulungelelwaniso lwezenzululwazi kunye nolufanelekileyo, ngaloo ndlela luqinisekisa umgangatho wemveliso ozinzileyo nozinzileyo.

3.PCB ibhodi yesekethe solder imaski isikrini ukuprinta-post-ukwenziwa komgangatho wokuhlola umgangatho:

Phuhlisa amanqanaba enkqubo yokuhlola umgangatho ofanelekileyo ukuqinisekisa ukubonwa kwangethuba kweengxaki ukuphepha ukwandiswa kwelahleko kunye nokunciphisa impembelelo ekusebenzeni kakuhle kwemveliso.

4.PCB ibhodi yesekethe solder imaski screen yoshicilelo-uqeqesho imveliso yabasebenzi:

Ukuphucula ukukwazi kwabasebenzi ukuchonga, ukuxilonga, ukuhlalutya kunye nokusombulula iingxaki zomgangatho wenkqubo, ukuphucula izakhono zobungcali kunye nokuqonda imigaqo yeengxaki ezimbi, ukuqhuba uvavanyo rhoqo kunye noqeqesho, kunye nokuqulunqa iinkqubo zokusebenza ezisemgangathweni ukuze abasebenzi bakwazi ukusebenza ngokufanelekileyo nangokuchanekileyo, kwaye baphendule. kunye nokusombulula iingxaki ezahlukeneyo ngexesha elifanelekileyo.imeko engxamisekileyo.

3. PCB ibhodi yesekethe solder imaski yoshicilelo lwesikrini ibangela umphezulu webhodi ukuba ube bomvu.Yintoni enokuyenza ngesishwankathelo

Ingxaki yebhodi yesekethe ye-PCB yebhodi ye-solder mask ibhodi yokushicilela ibhodi ebomvu yingxaki eqhelekileyo kwinkqubo yokuvelisa, kodwa ayikho ingxaki enzima.Ihlala incinci kwaye ikwinqanaba lokuqala, kwaye kulula ukwenzeka kwiifektri ezingaphucukanga nezisemgangathweni.Ukuyicombulula le ngxaki, kufuneka kugxininiswe kuqulunqwe iinkqubo zokusebenza ezisemgangathweni nezisemgangathweni, ukukhetha ibhodi efanelekileyo ye-PCB yebhodi yesekethe solder imaski isixhobo somatshini wokushicilela kunye nabaqhubi abaqeqeshiweyo ukunqanda ukwenzeka kweempazamo ezinjalo ezikumgangatho ophantsi, eziya kuchaphazela umgangatho wenkampani kunye nokubanzi. iinzuzo.

Ixesha lokuposa: Mar-12-2024