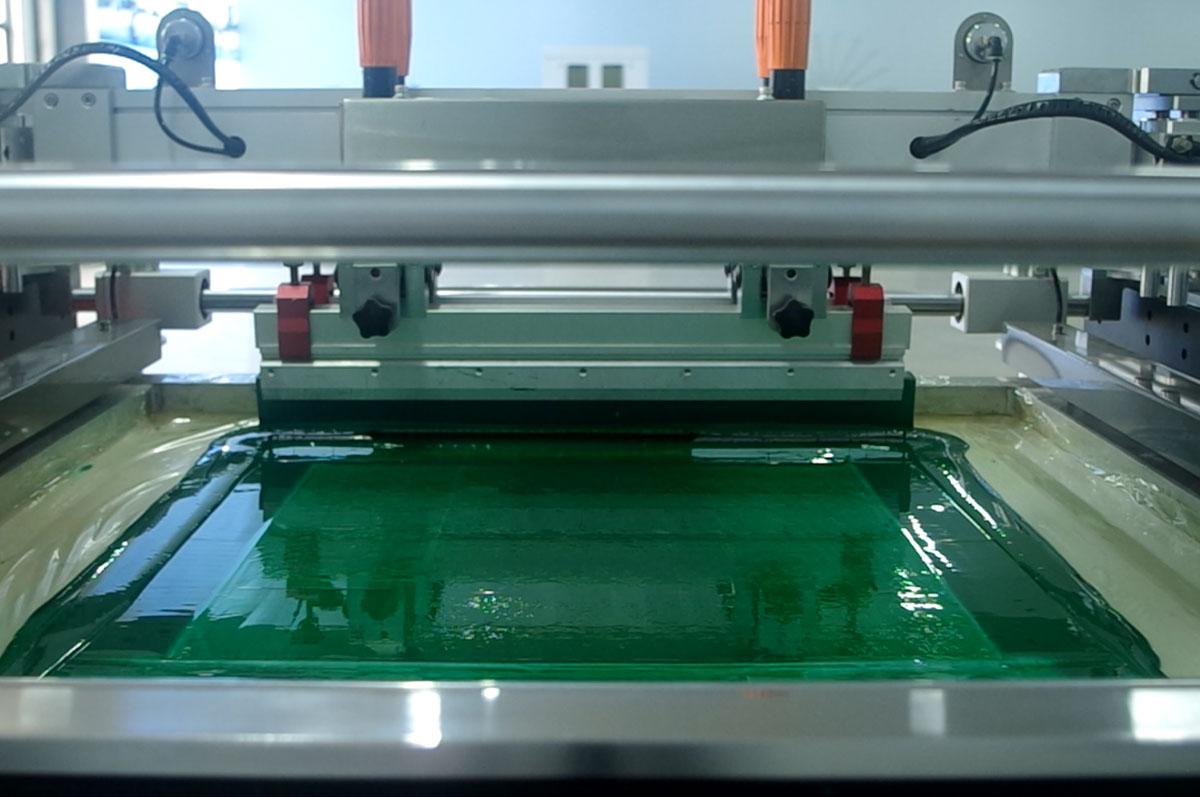

Umgangatho kunye nokusebenza kweebhodi zesekethe zePCB zidlala indima eqinisekileyo kulo lonke ishishini lemveliso ye-elektroniki.Inkqubo ye-mask efanayo ye-solder nayo iyindlela ebalulekileyo yokukhusela umgangatho webhodi yesekethe.Umgangatho PCB abavelisi 'solder imaski yoshicilelo iteknoloji screen kunye nezixhobo ziya kuba nempembelelo ebalulekileyo kumgangatho iibhodi PCB.Inempembelelo enkulu ekusebenzeni kwemveliso kunye neenzuzo ezibanzi zomzi-mveliso.Eli nqaku lisebenzisa iminyaka engama-20 yamava kwibhodi yesekethe ye-PCB yetekisi / iteknoloji yezixhobo ukwazisa kuni iingcebiso ezili-10 malunga nokusebenza kwenkqubo kunye nokugcinwa kwebhodi yesekethe ye-PCB yebhodi yokuthengisa imaski yokushicilela koomatshini bokushicilela isikrini!

1. Ingcebiso yoku-1

Kukho ulwazi oluninzi ekukhetheni umnatha wesikrini.Kwiimfuno ezahlukeneyo zoshicilelo, kufuneka usebenzise umnatha ofanelekileyo wekhusi ukufumana isiphumo esilindelekileyo soshicilelo.Nangona i-mesh encinci, eyona nto ifanelekileyo iinkcukacha eziprintiweyo ziya kuba, kodwa akuthethi ukuba i-mesh encinci, ingcono.Okungcono, ikakhulu kuxhomekeke ekuchanekeni kwezixhobo kunye neemfuno zoshicilelo zebhodi yePCB solder imaski yomatshini wokushicilela wesikrini.

2. Ingcebiso yesi-2

Uxinzelelo lwesikrini luhlala lumodareyitha, kuba xa uxinzelelo luncinci, isikrini siya kugxininiswa ngexesha lenkqubo kwaye sikhululeke, okukhokelela ekungacacisi ngokwaneleyo koshicilelo.Ngokuchasene noko, ukuba uxinzelelo luphezulu kakhulu, isikrini sinokuphulwa ngokuthe ngqo kwaye sonakaliswe., ngoko ke uhlengahlengiso loxinzelelo lwesikrini lukwavavanya amava omshicileli wesikrini.

3. Ingcebiso yesi-3

Isikrini kufuneka sicocwe kwaye sitshintshwe.Emva kwexesha elide lokuprintwa kwesikrini, i-inki iya kuhlala kwaye ivale isikrini, okukhokelela kwiimveliso ezineziphene.Ngoko ke, ukuhlolwa kunye nokulungiswa kweempazamo kufuneka kwenziwe ngaphambi nangemva kwemveliso nganye ukunqanda ukuchaphazela umgangatho wokushicilela kunye nokubangela ilahleko kunye nenkunkuma.

4. Ingcebiso yesi-4

Ifilimu yokushicilela kufuneka icace kwaye icoceke, kwaye kufuneka ihlolwe iziphene okanye imikrwelo.Ngaphambi kokusetyenziswa, i-adhesive photosensitive kufuneka isetyenziswe apho kuyimfuneko ukuqinisekisa ngokufanelekileyo ukucaca komfanekiso.

5. Ingcebiso yesi-5

Ukusetwa kweeparamitha zokushicilela kuya kuchaphazela ngokuthe ngqo isiphumo soshicilelo, ngoko ke uvavanyo lomatshini wokuvelisa kwangaphambili lubaluleke kakhulu.Uxinzelelo lokushicilela, ixesha kunye nesantya kufuneka luhlengahlengiswe kwiiparamitha ezifanelekileyo zokuprintwa kwemveliso yangoku, ngaloo ndlela kuphuculwe ngokufanelekileyo umgangatho, ukusebenza kakuhle kunye nokuzinza kokushicilela.Zama ukuphepha ibhodi yenkunkuma rework kunye nezinye iziganeko kangangoko kunokwenzeka.Kuba zininzi iimodeli zePCB, yinkcitho enkulu yexesha ukutshintsha imveliso kwaye uhlengahlengise umatshini ngalo lonke ixesha.Ikwaxhomekeke kumava kunye netekhnoloji yomshicileli wesikrini semaski solder, ngoko ke inqanaba lobukrelekrele lomshicileli wesikrini semaski solder, isantya sotshintsho lwemodeli kunye notshintsho lwemveliso lubaluleke kakhulu, oluchaphazela kakhulu ukusebenza kakuhle kwemveliso.

6. Ingcebiso yesi-6

I-inki yenye yezinto eziphambili kumgangatho we-solder mask screen printing.Ngoko ke, i-inki kufuneka ikhethwe kwimaski ezinikeleyo ye-solder ukuqinisekisa isiphumo soshicilelo lwesikrini.Okwesibini, umbala kunye nonyaka we-inki kufuneka ukhethwe ngokweemfuno zemaski ye-solder.

7. Ingcebiso yesi-7

Ukuthintela iingxaki ezifana nokuqiniswa kwe-inki, i-inki kufuneka ivuswe rhoqo ukuyigcina ikwimo ezinzileyo, ngaloo ndlela kuthintelwa ukuvaleka komnatha ngexesha lenkqubo yoshicilelo.

8. Ingcebiso yesi-8

Beka iliso kwiqondo lobushushu kunye nokufuma kokusingqongileyo.Ngenxa yokuba iqondo lobushushu kunye nokufuma kunempembelelo ethile kwi-fluidity kunye nokunamathela kwe-inki, kufuneka siphumelele iiparamitha zendawo yemveliso kwaye silungelelanise ngokufanelekileyo ukuphepha iziphumo ezingeyomfuneko kumgangatho woshicilelo lwesikrini.

9. Ingcebiso yesi-9

Funda kumava oshicilelo lwebhodi ye-PCB yebhodi yokuthengisa imaski, shwankathela idatha kunye neendlela kunye nobuchule, fumana amakhonkco achaphazela ukusebenza kakuhle kunye nomgangatho woshicilelo, kunye nokwandisa ukuhamba kwenkqubo, ngaloo ndlela kuzisa inzuzo kubavelisi bePCB.

10. Iingcebiso 10

Akukho nto ilunge ngaphezu kokushiywa.Kufuneka sinikele ingqalelo ekuhlolweni komgangatho wenyathelo ngalinye lemveliso ukuze siphephe ilahleko enkulu ngenxa yolawulo oluncinci.Zifumane kwangethuba ukunciphisa impembelelo.

Ngokulandela iingcebiso ezili-10 eziveliswe ngu-Xin Jinhui apha ngasentla, uya kuba nako ukugqiba inkqubo yoshicilelo lwebhodi yesekethe ye-PCB yebhodi yesekethe ye-solder imaski yesikrini ngcono kwaye ngokugudileyo, ngaloo ndlela kuphuculwe ukusebenza kakuhle kwemveliso kunye nomgangatho wemveliso, ukuphepha ilahleko kunye nenkcitho engeyomfuneko, kunye nokukhuthaza ngempumelelo iinzuzo ezibanzi. .ukuphuculwa.Ndiyathemba ukuba le intshayelelo ingentla inokunceda inkampani yakho ekusebenzeni, ekusebenziseni nasekugcinweni kwebhodi yesekethe ye-PCB yebhodi yokuthengisa imaski yokushicilela koomatshini bokushicilela kunye nakwinkqubo yemveliso!

Ixesha lokuposa: Mar-06-2024